The nickel aluminium bronze alloys are fairly complex materials and during manufacture require good control of the metal structure by attention to composition and heat treatment.

Nickel aluminum bronze chemical compatibility.

Aluminum brass bronze sand castings.

Because of this extensive chemical compatibility.

Check the chemical compatibility of aluminum with various chemicals solvents alcohols and other products.

As such it is the purpose of this publication to provide an engineering overview of the properties of the.

Paul foundry 954 minnehaha ave west st.

Aluminum chemical compatibility chart.

C95800 nickel aluminum bronze.

Chemical compatibility guide for metallic materials.

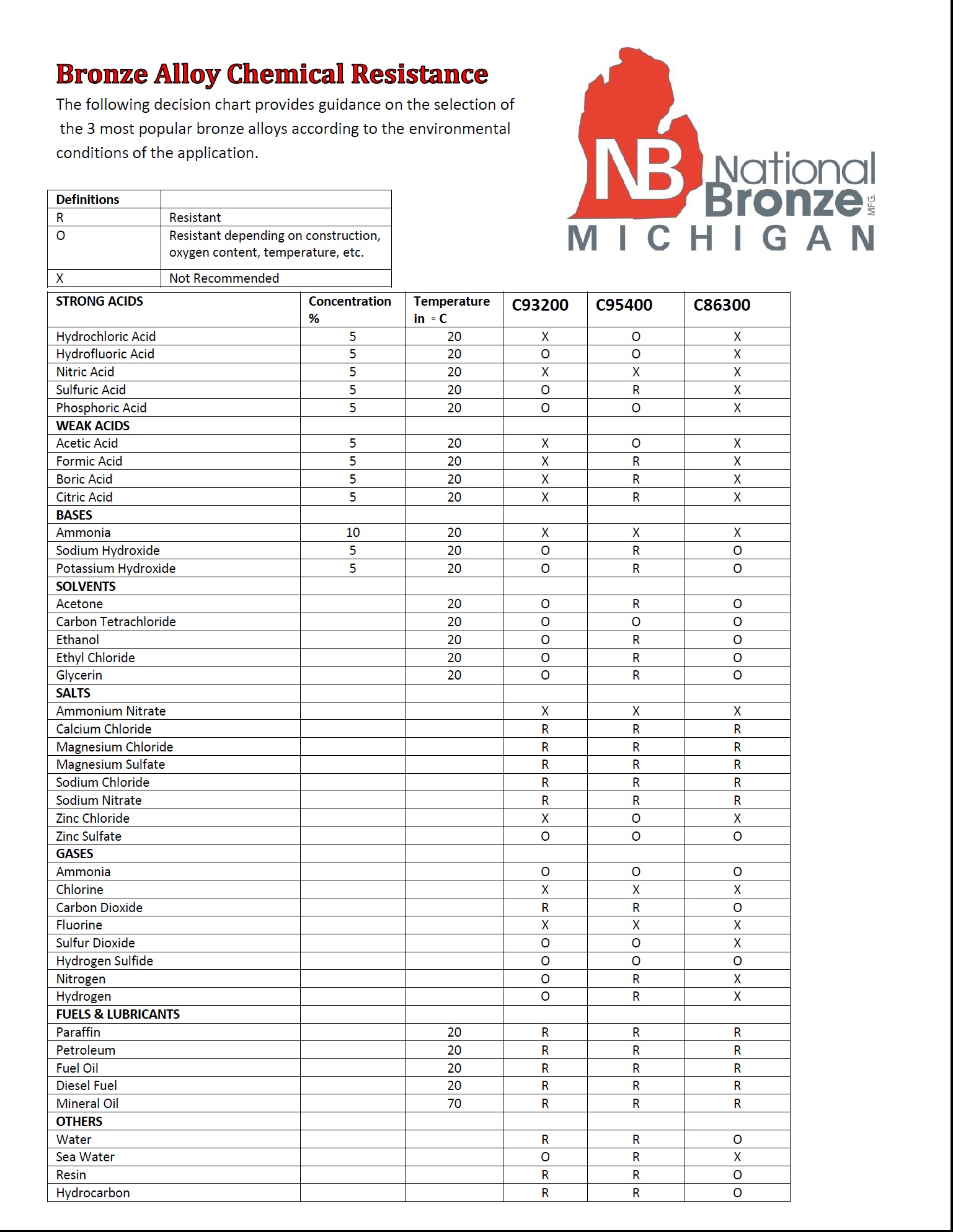

The different bronze alloys each have unique resistant qualities to various chemicals that make them the ideal bronze alloys for specific environments.

Chemical certifications radiography dye penetrant or.

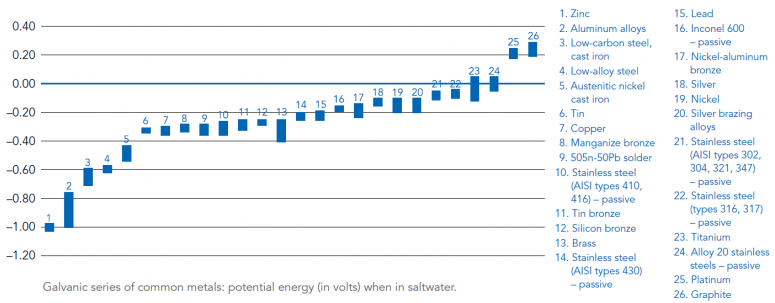

There are three conditions that must exist for galvanic corrosion to occur.

The information in this chart has been supplied by reputable sources and is to be used only as a guide in selecting equipment for appropriate chemical compatibility always test your equipment under the specific.

Specifications applications properties techniques corrosion resistance properties and enineering.

Magnesium zinc aluminum cadmium iron steel chromium brass copper bronze nickel monel stainless steel 1.

Quality engineering and design requires an understanding of material compatibility.

6 15 corrosion resistance of nickel aluminium bronze in chemical environments 6 15 1 sulphuric acid 6 15 2 acetic acid 6 15 3 hydrochloric acid 6 15 4 phosphoric acid 6 15 5 hydrofluoric acid 6 15 6 nitric acid 6 15 7 alkalis 6 15 8 salts 6 15 9 other corrosive chemical environments.

Galvanic corrosion some times called dissimilar metal corrosion is the process by which the materials in contact with each other oxidizes or corrodes.

Before permanent installation test the equipment with the chemicals and under the specific conditions of your application.

One of the many advantages of bronze alloys are their resistance to multiple chemicals.

Nibco chemical resistance guide for valves fittings.

We have developed a quick reference chart of the 3 most popular bronze alloys c93200 c95400 c86300 and.

The information in this chart has been supplied to cole parmer by other reputable sources and is to be used only as a guide in selecting equipment for appropriate chemical compatibility.

Where it is possible the unit will be subjected to high humidity that is not salt laden then the.

Aluminum bronze the most widely accepted disc material used in butterfly valves aluminum bronze is heat treatable and has the strength of steel.